Projects across industries have gotten a whole lot easier thanks to mini loaders. Compact and mighty, these essential tools go where larger machines can’t. Perfect for tig

ht spaces, they yield fantastic results in an instant – whether that’s in property maintenance, construction, or the great outdoors. But what makes a mini loader so special, and are they suitable for you? From machine makes to power tools, we’ll cover it all, so you can build a winning equipment lineup that gets the job done.

Table Of Contents:

- Mini Loaders: Small Size, Big Impact

- Types – they’re not just categories, they’re real tools with genuine applications.

- Engine Power and Type

- Operating Weight and Lift Capacity

- Hydraulic Flow and Pressure

- Operator Comfort and Visibility

- Safety Features

- Maintenance and Servicing

- Now we’ve reached the final curtain. The major highlights are in place – now, let’s distill them down and explore the residuals.

Mini Loaders: Small Size, Big Impact

Mini loaders, also known as compact loaders, are smaller versions of skid steer loaders and compact track loaders. Where space is tight and the ground is unforgiving, these little wonders prove their worth with precision handling and a miniature profile.

Don’t let their size fool you; these machines are powerful and can handle a wide range of tasks using various attachments. Whether digging, lifting, grading, or moving materials, a mini loader attachment likely suits your needs.

Attachments hold the key to unlocking a mini loader’s true potential – let’s take a closer look at what’s available.

Types – they’re not just categories, they’re real tools with genuine applications.

For any job or budget, there’s a mini loader out there to match. Think of each type as a puzzle piece – only by understanding its unique edges can you figure out where it fits in your operational landscape.

Wheel Loaders

These machines, like the compact wheel loaders offered by Cat ®, offer a balance of power, speed, and maneuverability. This balance makes them ideal for working in tight spaces where other machines might struggle. When every inch counts, their precision steering comes into play, enabling landscapes to conserve the integrity of lawns and surrounds with precise turns and minimal disturbance.

Key Benefits

- Precision steering for minimal disturbance

- Balance of power, speed, and maneuverability

- Ideal for working in tight spaces

Heavy-Duty Work

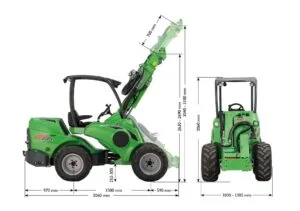

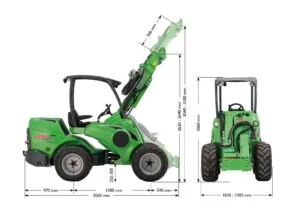

For heavy-duty work requiring higher lift capacities and faster travel speeds, exploring models like the Avant 800 series available in South Africa can be worthwhile. These machines are designed to handle demanding tasks with ease, making them perfect for large-scale projects.

Avant’s Mini Loaders in South Africa

Avant’s lineup of mini loaders in South Africa is seriously impressive, with a wide variety to choose from. Their machines are known for their reliability, versatility, and ease of use, making them a popular choice among professionals. With options to suit different needs and budgets, Avant’s mini loaders are definitely worth considering for any heavy-duty project.

These machines, like the compact wheel loaders offered by Cat ®, offer a balance of power, speed, and maneuverability. When every inch counts, their precision steering comes into play, enabling landscapes to conserve the integrity of lawns and surrounds with precise turns and minimal disturbance.

For heavy-duty work requiring higher lift capacities and faster travel speeds, exploring models like the Avant 800 series available in South Africa can be worthwhile. Avant’s lineup of mini loaders in South Africa is seriously impressive, with a wide variety to choose from.

Articulated Loaders

Featuring a pivot point between the front and rear axles, articulated loaders like the Avant machine offer exceptional maneuverability, surpassing even traditional skid loaders in navigating tight spaces with minimal ground impact.

Landscaping, agriculture, and construction projects thrive when you can move quickly – this design makes it happen.

Track Loaders

Equipped with tracks instead of wheels, track loaders offer superior traction and stability on challenging terrain. Get Ready for Traction Unlimited. Taking cues from off-roaders, this contraption muscles its way up gradients and grip-and-rips through slimy messes without breaking stride.

You’ll often find track loaders employed in construction, forestry, and large-scale landscaping endeavors.

Assessing Key Features: Factors That Matter

Knowing What Matters

Knowing the key features of mini loaders can aid in selecting the optimal model for specific operational requirements. In a competitive market, understanding what sets one loader apart from another is crucial. It’s the little things that often make a big difference.

Operational Efficiency

- Lift Capacity: The maximum weight a mini loader can lift and transport safely. Ensure the chosen model can handle the expected payload.

- Digging Depth: The maximum depth the loader’s bucket can reach. This affects the type of tasks the loader can perform.

Performance and Productivity

- Engine Power: The horsepower and torque of the engine, influencing the loader’s speed and ability to handle heavy loads.

- Hydraulic System: The pressure and flow rate of the hydraulic system, affecting the loader’s digging and lifting capabilities.

Safety and Ergonomics

- Operator Comfort: The design and features of the operator’s cabin, impacting fatigue and overall user experience.

- Safety Features: The inclusion of features such as alarms, cameras, and emergency stops to ensure a safe working environment.

Maintenance and Durability

- Service Access: The ease of accessing key components for maintenance and repairs, reducing downtime and costs.

- Material Quality: The quality of materials used in the loader’s construction, affecting its durability and lifespan.

Additional Features

- Attachments and Accessories: The range of available attachments and accessories, expanding the loader’s capabilities and versatility.

- Technology and Integration: The integration of advanced technologies, such as GPS and telematics, to enhance performance and monitoring.

Knowing the key features of mini loaders can aid in selecting the optimal model for specific operational requirements. The nitty-gritty details are what set successful efforts apart – so let’s break them down.

Engine Power and Type

The engine is the heart of the mini loader, and its power and type can significantly impact performance. Diesel engines are commonly used in mini loaders due to their high torque output and fuel efficiency. However, electric and petrol engines are also available, offering alternative options for specific applications.

Operating Weight and Lift Capacity

The operating weight and lift capacity of a mini loader are crucial factors to consider. A higher operating weight typically translates to increased stability, while a higher lift capacity enables the loader to handle heavier payloads. Compact models with lower operating weights are ideal for tight spaces, whereas heavy-duty models with higher lift capacities are better suited for demanding tasks.

Hydraulic Flow and Pressure

Hydraulic flow and pressure determine the loader’s ability to power attachments and perform tasks efficiently. Higher hydraulic flow rates enable faster cycle times, while higher hydraulic pressures provide the force needed for demanding applications.

Operator Comfort and Visibility

A comfortable and ergonomic operator station is vital for reducing fatigue and improving productivity. This is especially important for operators who spend long hours on the job, as discomfort can lead to decreased focus and accuracy.

Adjustable Seating

Adjustable seating is a key component of an ergonomic operator station. This allows the operator to customize their seating position to fit their individual needs, reducing strain on the back and legs.

Clear Visibility

Clear visibility is essential for operators to perform their tasks efficiently and safely. This includes an unobstructed view of the surrounding area, as well as easy-to-read displays and gauges.

Intuitive Controls

Intuitive controls are designed to reduce operator error and improve overall performance. This includes logical control layouts, clear labeling, and minimal complexity.

The Benefits of a Positive Operator Experience

A positive operator experience has numerous benefits, including:

- Improved Productivity: Comfortable and focused operators are more productive and efficient.

- Reduced Fatigue: Ergonomic design reduces physical and mental strain, leading to less fatigue and decreased error rates.

- Enhanced Safety: A comfortable and focused operator is better equipped to respond to unexpected situations and make safe decisions.

By prioritizing operator comfort and visibility, equipment manufacturers can create machines that are not only more efficient but also safer and more enjoyable to operate.

A comfortable and ergonomic operator station is vital for reducing fatigue and improving productivity. Adjustable seating, clear visibility, and intuitive controls all contribute to a positive operator experience.

Attachment Versatility

The ability to use various attachments expands the mini loader’s capabilities and increases its value. This flexibility is a key advantage of mini loaders, allowing them to adapt to different tasks and applications.

Simplifying Attachment Changes

Quick-attach systems simplify the process of switching between attachments, reducing downtime and increasing productivity. These systems enable operators to quickly and easily change attachments, without the need for additional tools or expertise.

Expanding Attachment Options

Electrical and hydraulic interfaces enable the use of a wide range of attachments, from buckets and brooms to augers and grapples. This versatility allows mini loaders to tackle a variety of tasks, from material handling and excavation to landscaping and demolition.

Increased Value and ROI

By expanding the mini loader’s capabilities, attachments increase its value and return on investment (ROI). With the ability to perform a wide range of tasks, mini loaders become an essential tool for any construction, landscaping, or agricultural operation.

The ability to use various attachments expands the mini loader’s capabilities and increases its value. Quick-attach systems simplify the process of switching between attachments, while electrical and hydraulic interfaces enable the use of a wide range of attachments.

Safety Features

Protecting Operators and Bystanders

Safety features are essential for protecting operators and bystanders from potential hazards on the job site. These features play a critical role in preventing accidents and ensuring a safe working environment.

Rollover Protection Structures (ROPS)

ROPS are a crucial safety feature that protects operators in the event of a rollover accident. These structures are designed to absorb the impact of a rollover, reducing the risk of injury or fatality.

Back-up Alarms

Back-up alarms are another vital safety feature that alerts bystanders of the machine’s movement. These alarms are especially important in noisy environments where visibility may be limited.

Clear Visibility

Clear visibility is essential for safe operation. A well-designed machine with minimal blind spots enables operators to see their surroundings, reducing the risk of accidents.

By incorporating these safety features, operators and bystanders can work with confidence, knowing they are protected from potential hazards.

Safety features are essential for protecting operators and bystanders. Rollover protection structures, back-up alarms, and clear visibility all contribute to a safer working environment.

Maintenance and Servicing

Easy maintenance and servicing are critical for minimizing downtime and reducing operating costs. Accessible components, simple maintenance procedures, and extended service intervals all help to keep the mini loader running efficiently.

Knowing the key features of mini loaders can aid in selecting the optimal model for specific operational requirements. The nitty-gritty details are what set successful efforts apart – so let’s break them down.

Lift Capacity and Height

Consider the weight and height of the materials you’ll be lifting. Look into loaders like the Avant 845, renowned for their lifting capacity, if you’re handling heavy loads – they even stand out as Skidsteer Killers .

For general landscaping and lighter lifting tasks, smaller-capacity loaders in the 500 series, might be more suitable.

Work smarter, not harder – that’s the essence of this approach, which discards unnecessary frills and gets the job done efficiently.

Engine Power

A machine’s engine power dictates its performance capabilities. Boosting horsepower gets you the muscle you need for demanding tasks like digging, grading, and hauling heavy loads – it’s the difference between finishing on time and deadline extensions.

A lower horsepower engine might be adequate if you primarily need a machine for loading and unloading light materials or carrying out less demanding work. The type of engine – diesel or electric – is also crucial.

Attachments and Versatility

A wide range of attachments makes a mini loader multifunctional. Think carefully about the practical tasks you’re about to take on.

Slap on a bucket, pallet fork, auger, trencher, or broom, and your mini loader transforms into a multi-talented workhorse.

Make sure the attachments you choose are a perfect match for your loader model – it’s the secret to top performance and safety.

Now we’ve reached the final curtain. The major highlights are in place – now, let’s distill them down and explore the residuals.

Whether you’re tasking them with moving heavy loads or tackling precision jobs, mini loaders consistently deliver, proving themselves to be flexible, reliable, and disarmingly efficient machines. A mini loader is only as good as its specs, so don’t forget to factor in lift capacity, engine power, and attachment options when making your decision – not to mention the ground you’ll be covering.

“To squeeze every last drop of efficiency out of your operations, you need to pinpoint the manufacturers and suppliers that cater directly to your needs. Only then can you truly expect to see a marked improvement in productivity and returns.”

So, there you have it – everything you need to know about mini loaders confidently.